对可持续、高性能材料日益增长的需求,正推动着利用储量丰富的生物质(特别是纤维素)来替代石油基塑料的研究。然而,纤维素的有效改性和功能化常常受到复杂加工工艺和有限性能可调性的制约。

近日,南京林业大学李仁爱博士等人在Science China Materials发表研究论文,报道了一种基于乙基纤维素/百里香酚低共熔体系的创新“活性”绿色介质策略,该策略无需外加催化剂或引发剂,即可实现低共熔组分的原位化学改性并构筑动态自适应网络。

本文要点

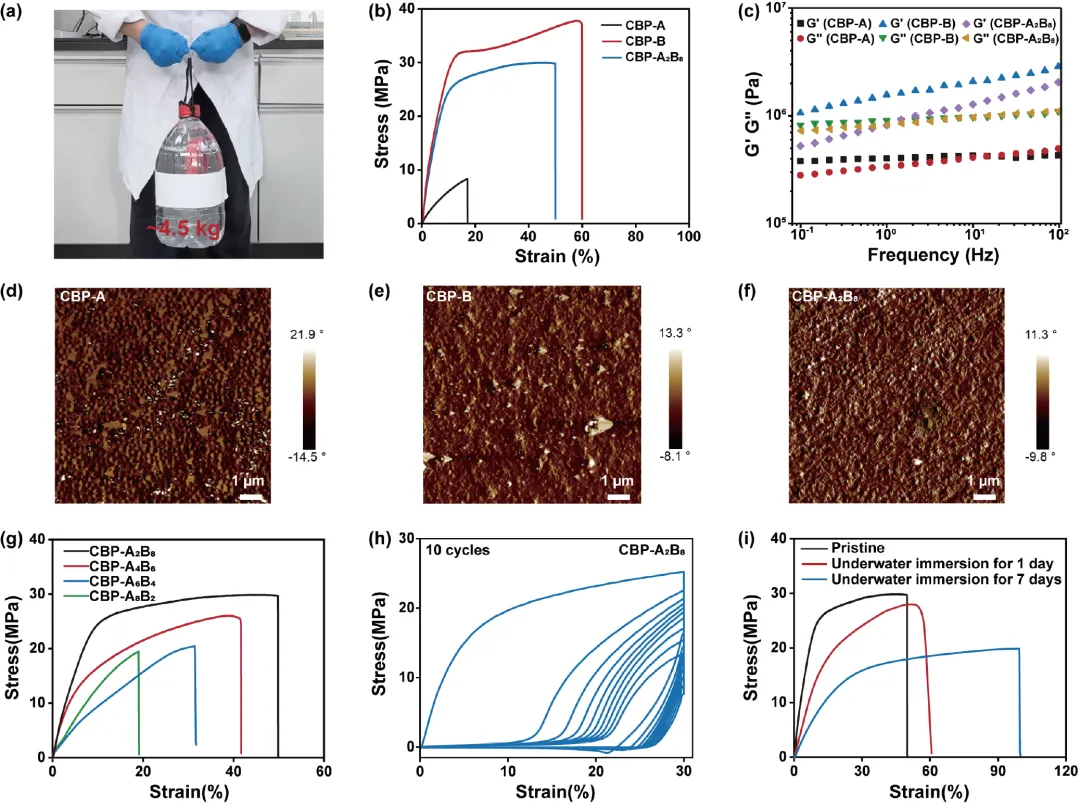

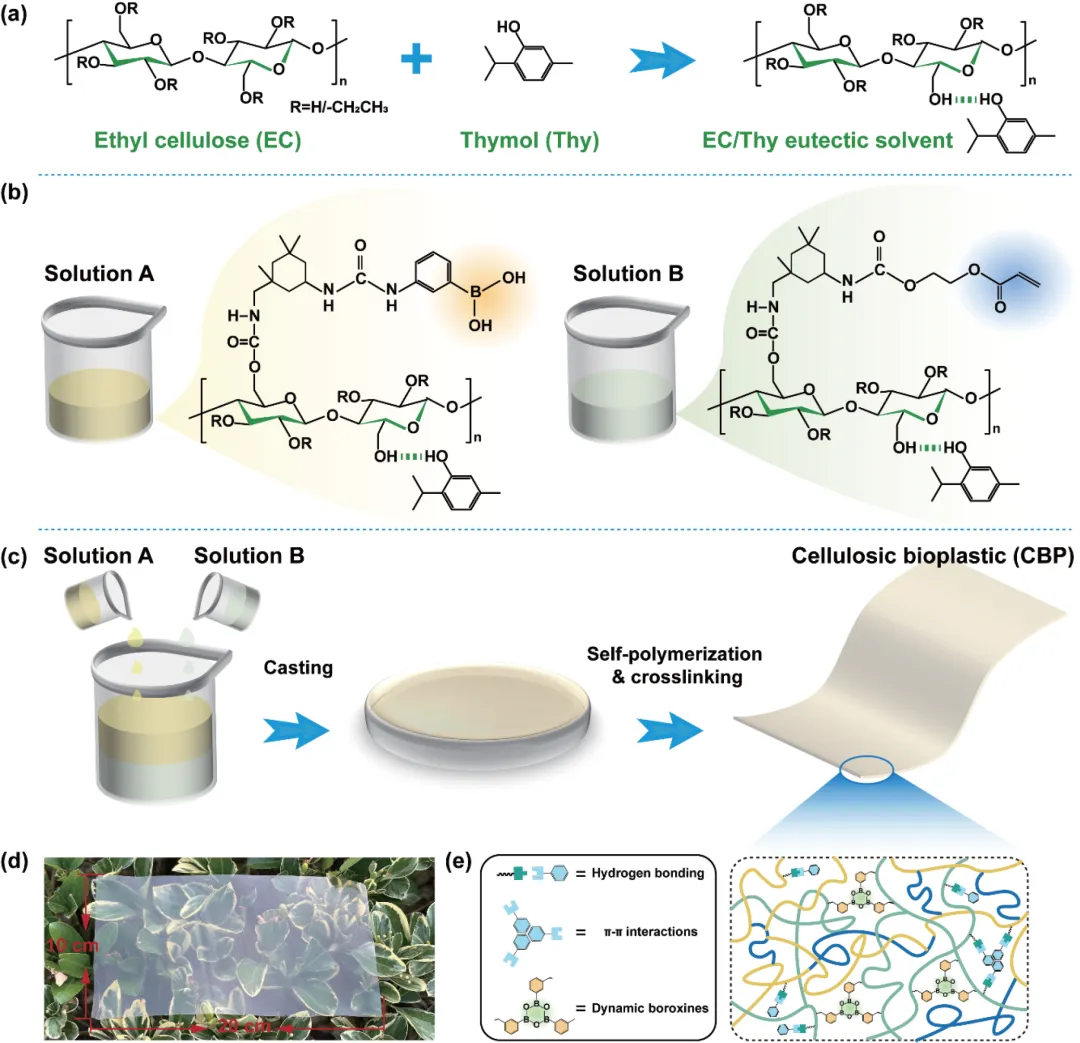

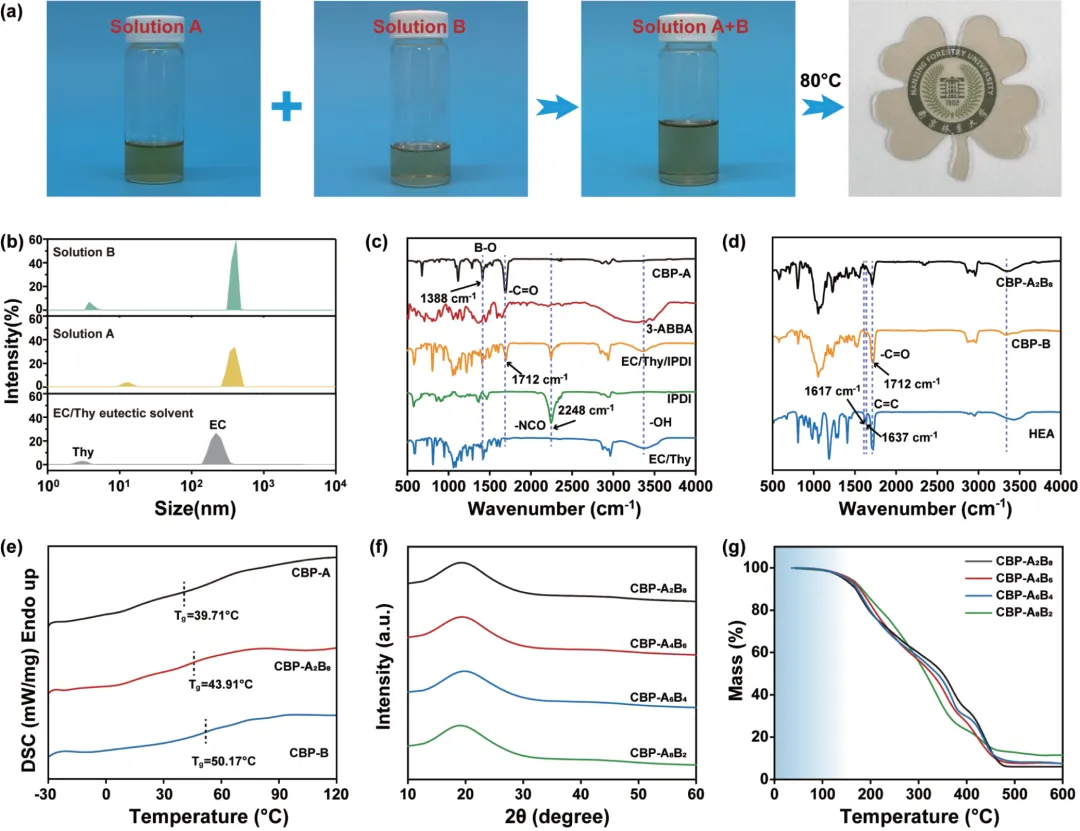

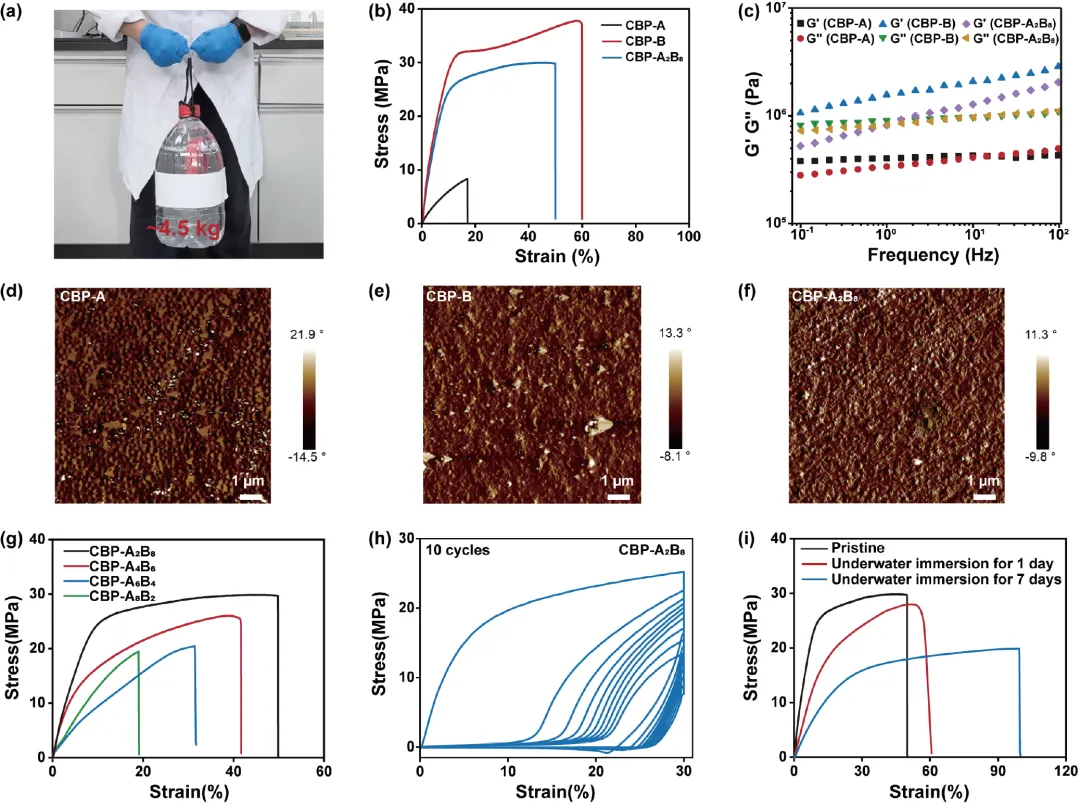

1) 通过精确的分子设计,动态硼氧六环网络和丙烯酸酯交联网络被协同地引入到纤维素基生物塑料(CBP)基体中。2) 所得的CBP-A2B8材料表现出优异的光学透明度(约85%)、卓越的力学性能(拉伸强度约30 MPa)、简便的热加工性以及闭环可回收性。即使在经历20次热压循环回收后,其化学结构和力学性能依然保持高度稳定。在自然环境下,该材料可在大约100天内完全生物降解。3) 该生物塑料与银纳米线复合可制备出高性能的柔性透明导电薄膜,并成功应用于可定制化的电致发光器件中。在器件使用寿命结束后,通过简单的溶剂法即可实现各组分(银纳米线和CBP基体)的高效分离与回收。这种由低共熔体系介导的策略,为开发具有闭环生命周期的可持续、高性能生物塑料提供了一条新路径。Figure 1.(a) Scheme for the preparation of EC/Thy eutectic solvent. (b) Chemical modification of dynamic B–O bonds in solution A and C=C double bonds in solution B, respectively. (c) Preparation of multifunctional CBPs without any catalyst and initiator by mixing solution A with solution B. (d) Optical photograph of a large format (10 cm × 20 cm) CBP prepared by the solution casting method. (e) CBP network with abundant multiple interactions such as dynamic B–O bonds, hydrogen bonds, and π-π interactions.Figure 2.(a) CBPs can be successfully prepared by physically mixing solution A and solution B in a certain mass ratio and holding at 80°C for a certain period of time. (b) DLS spectra of EC/Thy eutectic solvent, solution A, and solution B. (c, d) FTIR spectra before and after synthesis of CBPs. (e) DSC curves of the prepared CBP-A, CBP-B, and CBP-A2B8. XRD curves (f) and TGA spectra (g) of different CBPs prepared at different mass ratios for solution A and solution B. Figure 3.(a) A piece of ~0.3 g CBP-A2B8 film can lift a ~4.5 kg load; (b) Stress-strain curves of prepared CBP-A, CBP-B and CBP-A2B8; (c) Storage modulus (G’) and loss modulus (G”) as functions of frequency of CBP-A, CBP-B and CBP-A2B8; (d–f) AFM phase images of prepared CBP-A, CBP-B and CBP-A2B8; (g) Stress-strain curves of CBPs prepared by solution A and solution B at different mass ratios; (h) Stress-strain curves of CBP-A2B8 after 10 cycles of cyclic stretching. (i) Stress-strain curves of the prepared CBP-A2B8 after different times of underwater immersion.

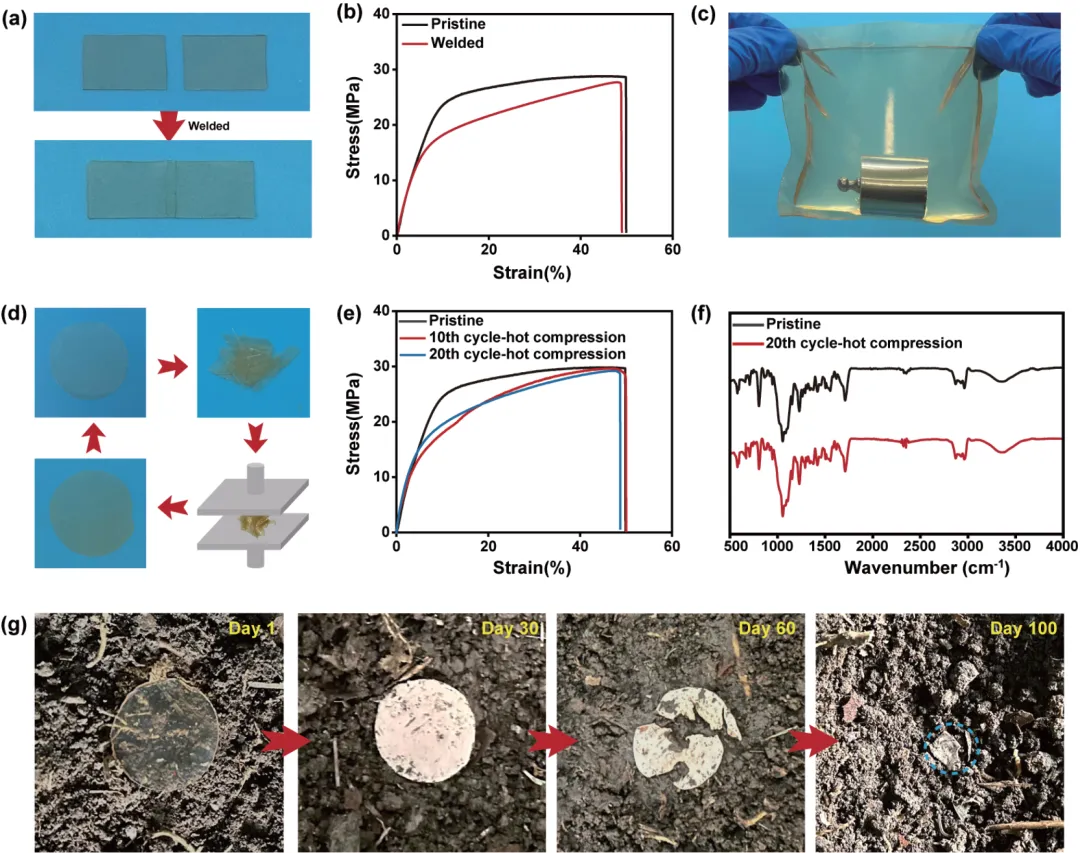

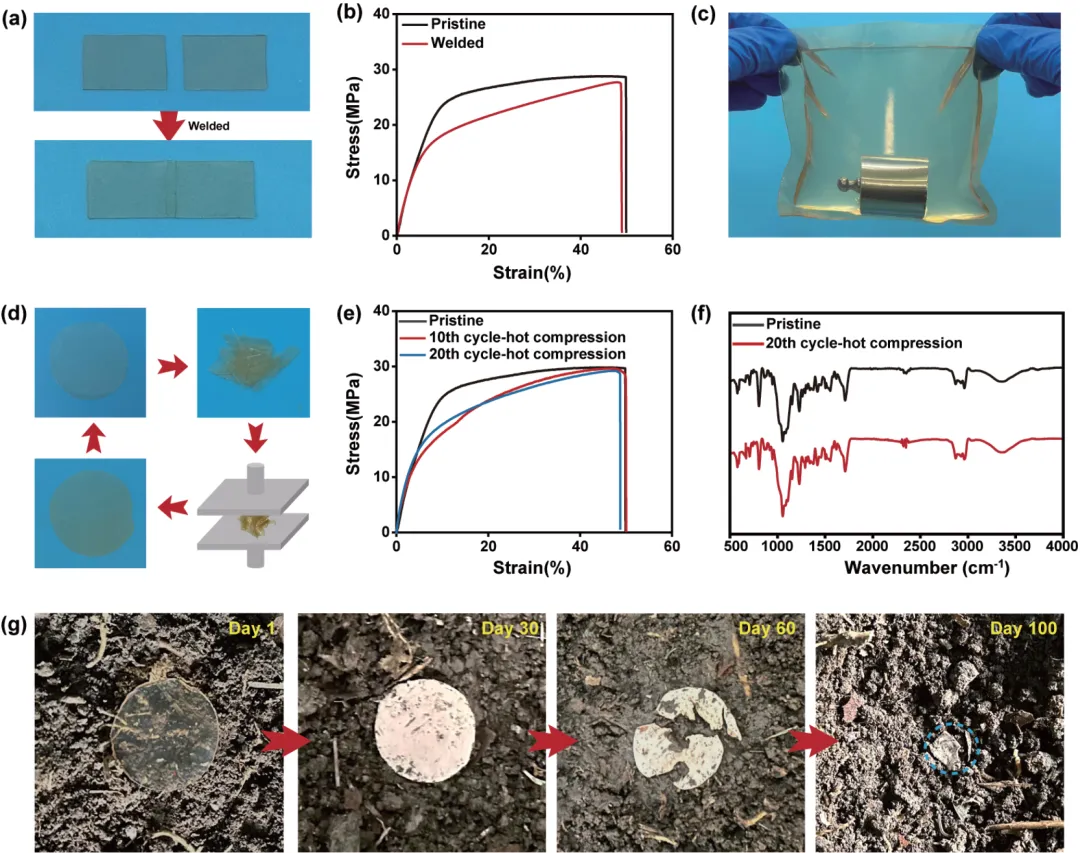

Figure 3.(a) A piece of ~0.3 g CBP-A2B8 film can lift a ~4.5 kg load; (b) Stress-strain curves of prepared CBP-A, CBP-B and CBP-A2B8; (c) Storage modulus (G’) and loss modulus (G”) as functions of frequency of CBP-A, CBP-B and CBP-A2B8; (d–f) AFM phase images of prepared CBP-A, CBP-B and CBP-A2B8; (g) Stress-strain curves of CBPs prepared by solution A and solution B at different mass ratios; (h) Stress-strain curves of CBP-A2B8 after 10 cycles of cyclic stretching. (i) Stress-strain curves of the prepared CBP-A2B8 after different times of underwater immersion. Figure 4.(a) Two pieces of CBP-A2B8 can be ‘welded’ by hot compression. (b) The ‘welded’ CBP-A2B8 exhibits approximately the same mechanical properties as the initial sample. (c) CBP-A2B8 film can be easily prepared in the form of a transparent bag that can hold water by hot compression. (d) CBP-A2B8 can be quickly recycled by hot compression after being cut into pieces. (e) CBP-A2B8 exhibits excellent mechanical properties after up to 20 consecutive hot-compression cycles. (f) FTIR spectrum of CBP-A2B8 after 20 cycles of recycling compared to the initial sample. (g) Photographs showing the biodegradation of a CBP-A2B8 film over 100 days. The experiment was conducted in Nanjing, China (32°N, 118°E) from July to October 2024. Samples were placed on natural garden soil and exposed to ambient environmental conditions (average daily temperature: ~25°C; average relative humidity: ~65%; natural diurnal sunlight cycles.

Figure 4.(a) Two pieces of CBP-A2B8 can be ‘welded’ by hot compression. (b) The ‘welded’ CBP-A2B8 exhibits approximately the same mechanical properties as the initial sample. (c) CBP-A2B8 film can be easily prepared in the form of a transparent bag that can hold water by hot compression. (d) CBP-A2B8 can be quickly recycled by hot compression after being cut into pieces. (e) CBP-A2B8 exhibits excellent mechanical properties after up to 20 consecutive hot-compression cycles. (f) FTIR spectrum of CBP-A2B8 after 20 cycles of recycling compared to the initial sample. (g) Photographs showing the biodegradation of a CBP-A2B8 film over 100 days. The experiment was conducted in Nanjing, China (32°N, 118°E) from July to October 2024. Samples were placed on natural garden soil and exposed to ambient environmental conditions (average daily temperature: ~25°C; average relative humidity: ~65%; natural diurnal sunlight cycles.

Huanhuan Wu(武欢欢) received her Bachelor’s degree from Nanjing Forestry University in 2022. Currently, she is studying for her Master’s degree at the College of Light Industry and Food Science, Nanjing Forestry University, majoring in materials and chemical engineering. Her current research interests include bioplastics and green degradable electronic materials.

Ren’ai Li(李仁爱) received his PhD degree in pulp and paper engineering from South China University of Technology in June 2019. After completing his postdoctoral work in June 2021, he joined the College of Light Industry and Food Science at Nanjing Forestry University. His main research interests focus on the design and development of bioplastics, natural functional polymer materials, and flexible printed electronic devices.

Huanhuan Wu, Ren’ai Li. Recyclable, reprocessable, and biodegradable cellulosic bioplastics enabled by a reactive eutectic network. Sci. China Mater. (2026).https://doi.org/10.1007/s40843-025-3871-9

点击左下角“阅读原文”,阅读以上文章PDF原文

点击左下角“阅读原文”,阅读以上文章PDF原文

点击左下角“阅读原文”,阅读以上文章PDF原文

点击左下角“阅读原文”,阅读以上文章PDF原文